OUR ACTIVITIES

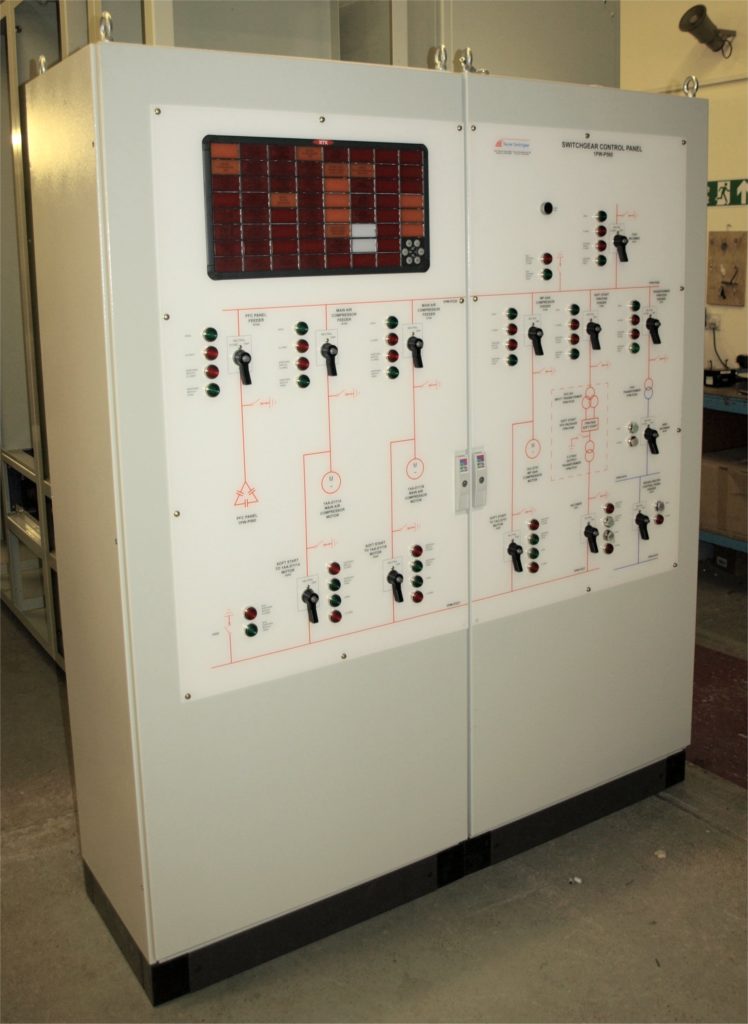

Our engineering department has wide experience in meeting customer’s Switchgear, Control and Instrumentation requirements.

Method statements, risk assessments are provided and reviews of health & safety, environmental requirements are undertaken.

All products prior to leaving our factory are extensively tested for quality and performance.

This ensures safety and reliability during operation and service.

Twyver Switchgear have designed, built, installed and commissioned “LV Distribution Switchboards” for a wide range of industries and customers both at home and abroad.

Reputation of switchboards manufactured by Twyver Switchgear:

Quality

Reliability

Ease of access when terminating cables

Extendable with minimum of disruption on site

Ease of access for maintenance

Twyver Switchgear design and build a range of Sub-Distribution Switchboards for ratings of 800 amps and below.

Customers can choose from our:

Custom built range

Modular design range

Customer built range

Our “Custom built range” is ideal where space is at a premium and has a reputation for quality & reliability.

This range is based on:

Compact front access design

Top or bottom cable entry

ASTA certified bus bar systems

Choice of paint colour / finish

Moulded case circuit breakers or fuse switch units

Ingress ratings up to IP65

In 2017, as Switchgear specialists, Twyver executed a Smart Panel project with a new client. Having presented the Smart Panel at the Smart Factory Expo (NEC, Birmingham) last November 2016 for the first time, this is the first order of the Twyver Smart Panel allowing remote control/notifications via a Smartphone.

The project will entail the supply of a generator and the addition of an auto-changeover section to an existing Switchboard, the changeover section will be complete with outgoing supplies and automatic control.

One of the client major criteria is the special requirement of automatic text message response to allow the client to monitor the status of the generator (e.g. when the Generator is called to start and when the system returns to mains and the Generator stops). Being aware of the status of the board at all times will allow the client to monitor fuel use and maintenance requirements on the generator.

Containerised Switchrooms are designed taking into account customers detailed requirements.

Recent Twyver Switchgear Containerised Switchrooms have included High Voltage Switchgear, cast resin power transformers, LV. Distribution switchboards, power factor correction equipment, battery charging / switchgear tripping units, instrumentation / power monitoring devices, air conditioning, emergency lighting equipment together with general power and lighting.

The Containerised Switchroom Solution is often quicker and more cost effective than traditional brick built options.

A containerised switchroom can be readily installed either at ground or roof level.

Twyver Switchgear have designed, built, installed, tested and commissioned Packaged Sub-Stations for a many customers within the industrial and retail sectors and have a reputation for:

Quality

Reliability

Performance

Easy of access

Package Sub-Stations enable significant savings to be achieved over traditional systems with:

Reduced Cabling costs

Reduced Civil engineering costs

Reduced Maintenance costs

Reduced Space requirements

Twyver Switchgear have designed, built, installed and commissioned “Motor Control Centres” and Instrument Panels for numerous industries and customers at both home and abroad.

Recent applications:

Quarries

Industrial Gas Plants

Water / Sewage Treatment Works

Automobile manufacture

Nuclear Facilities

Aviation industry

Food Processing

In addition to our normal range of Switchboards and Motor Control Centres, we are able to manufacture weatherproof versions.

Our cubicle design has been successfully tested for ingress protection (IP Rating) by the British Standards Institution.

Recent projects for weatherproof equipment have included:

Motor Control Centres

LV. Switchboards

Roof mounted Cast Resin Transformer

Emergency Response

Our team of experts are on standby for our contract customers every day of the year, and are able to respond to critical onsite emergencies within guaranteed timescales of as little as 4 hours.

Being part of VINCI Energies, we are able to leverage our significant in-house manufacturing capability and supply chain to quickly solve and rectify problems.

Our aim is minimise any power downtime to your business and reduce the future risk by the use of onsite crash kits, critical spares.

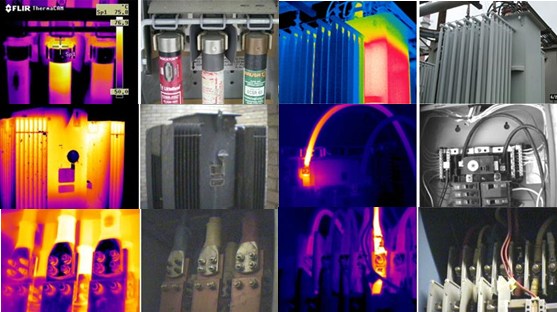

Thermal Imaging

As electrical connections become loose, the change in resistance causes increased temperature which can lead to component failure and unplanned outages / injuries. If left unchecked, heat can rise to a point that connections may melt and break the circuit; as a result, fires may occur. Thermography can quickly locate hot spots, determine the severity of the problem and help to establish the time frame in which the equipment should be repaired. If not rectified this could lead to a single point of failure and subsequent loss of supply.

With the increasing demands on building service supplies, the need for security of these supplies is absolutely critical.

Loss of supply can have the following consequences:

– Loss of life

– Major financial loss

– Loss of critical data

Regular, planned thermographic surveys by Twyver provide clients with fully detailed visual, written and electronic reports on the condition and performance of their equipment, together with appropriate recommendations and advice.

In many industries, mechanical systems serve as the backbone of operations. Typically when mechanical components become worn and less efficient, the heat emitted will increase. Consequently the temperature of faulty components or systems will increase rapidly before failure. Typical mechanical systems monitored in a predictive maintenance infrared programme include bearings, motors, pumps, compressors and conveyors.

Non-Invasive Service

Regular monitoring and verification checks will identify signs of degradation, which could result in future faults.

A typical Non-invasive Service visit follows our strict Safe Working Procedures and may include the following:

- Full visual inspection (where safely accessible)

- Thermographic survey

- Check function of meters and record values

- Check function and status of electronic surge protection

- Check operation of lamps and indicators

- Check operation of fans and thermostats

- Verify control circuit fuse continuity

- Record LV transformer values where applicable

- Clean of safely accessible surfaces / compartments

- AHF / STS servicing where applicable (in bypass)

Fully Isolated Service

A planned Fully Isolated Service should be completed every 3 to 5 years. We are expert in planning and delivering an Isolated Service to minimise the impact on your business. These are usually completed out of hours.

A typical Fully Isolated Service may include the following:

- Prior to shutdown, live visual inspection of lamps and meters with readings noted

- Verify torque tightness of all power connections

- Check tightness and mechanical operation of all switching devices

- Check tightness and condition of pan assembly connections

- Check tightness and condition of outgoing terminals

- Check operation of lamps, indicators, fans, thermostats, control circuit fuse continuity

- Check operation of doors and interlocks

- Clean of panels inside and out where safely accessible, removal of debris / particulates / residue and photograph for inclusion within the report

- Full torque testing and cleaning of HV transformer and enclosure

- Insulation and continuity testing of LV transformer

- ACB / MCCB tested and serviced

- Active Harmonic Filter (AHF) servicing

- Static Transfer Switch (STS) servicing

- Power Factor Correction (PFC) servicing

Customer Tracking

We offer training packages either on-site or at our own facilities. All sessions are delivered by our Expert Engineers.

Typically a classroom session, for up to 8 people, is held for the first half of the day followed by hands-on operational experience within the installation.

We offer the following training:

LV switchgear – Basics

LV switchgear – Intermediate

LV switchgear – Advanced

Busway Tapoff Installation

Power Management System /Energy Management System Training

Extended Warranty

The Twyver Warranty is 12 months from commissioning. Should you wish to extend this we can provide Warranties for up to 5 years.

Customers who sign up for Extended Warranties benefit from the following:

- 24 hour target response time

- All parts, consumables and labour included

- Technical support during normal working hours

Please note all Warranties exclude damage resulting from misuse, negligence, vandalism or Acts of God (fire, flood, etc).

Critical Spares Kit

elp avoid costly Switchgear failure with a Critical Spares Pack from Twyver.

Our experience in bespoke Switchgear design allows us to identify the components that are critical to supporting your load and create a dedicated Critical Spares Pack for you to hold on site. This ensures critical parts are on hand to Engineers responding to emergency call-outs, reducing downtime, disruption and cost of any outage.

24 hours Technical Support

Our dedicated team of Expert Engineers are always on standby 24/7 for our Contract Customers.

This service provides technical support over the phone, assisting in timely identification of system faults and their resolution. Where required the call is escalated to Emergency Response to provide a speedy on-site solution.

Power Quality Surveys

Poor power quality can increase energy costs and lead to early equipment failure.

Our Experts will use data logging equipment to produce a Power Quality Survey report with specific recommended improvement actions to benefit your business.

A typical Power Quality Survey will cover:

- Supply efficiency

- Imbalanced phase voltages

- Harmonic distortion

Power Management Systems & Energy Management Systems Servicing

Our EMS/PMS service contracts include scheduled site visits to provide:

Communications network checks

Meter operation checks

Thermal sensor operation checks

Review of alarms and setting adjustments as required

Database backup and management

Install of critical service packs or hot fixes

Minor system adjustments as required

Advice on use of system and potential upgrades

Switchboard Survey

Gain a complete understanding of any existing power system with the Switchboard Survey services of Twyver. Ideal for Customers moving into new buildings or to review the suitability of older Switchboards for refurbishment or upgrade.

All Surveys are carried out in accordance with BS7671 and BS6423:1983 and typically include:

- Segregation & IP rating

- Earthing

- Insulation levels

- Cabling terminations and sizing

- Busbar details

- Production of general arrangement / electrical schematic drawings

- Survey all metering arrangements

- Test and detail all protective devices to enable full discrimination study

- Recommendations and budgeted remedial costs

Retrofit and Modifications

Retrofit and onsite modifications are designed to:

- Comply with safety regulations

- Reduce your operating costs

- Improve operational performance

- Extend the life of your equipment

Our Expert Engineers are familiar with all brands of Switchboards.